Details

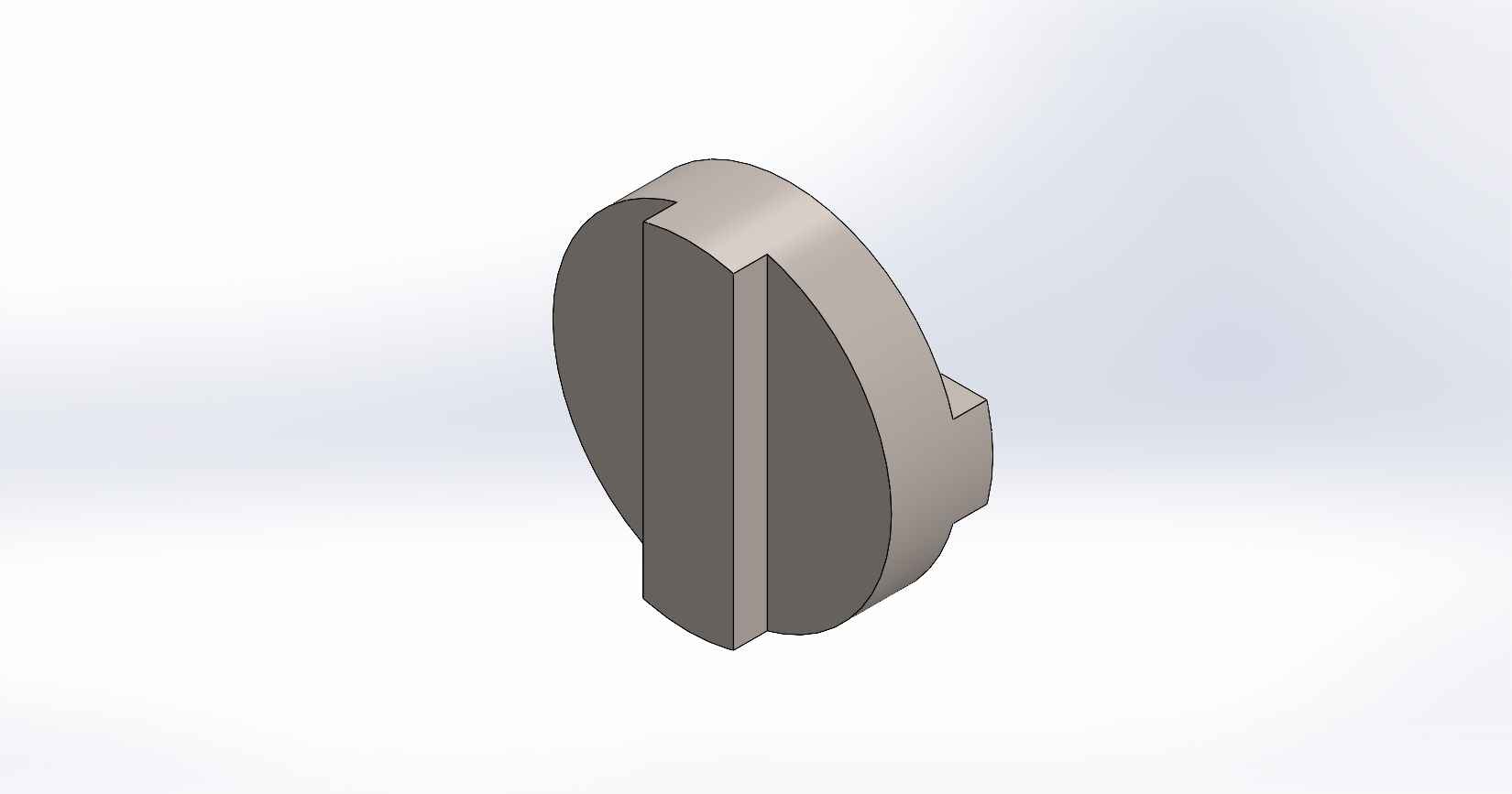

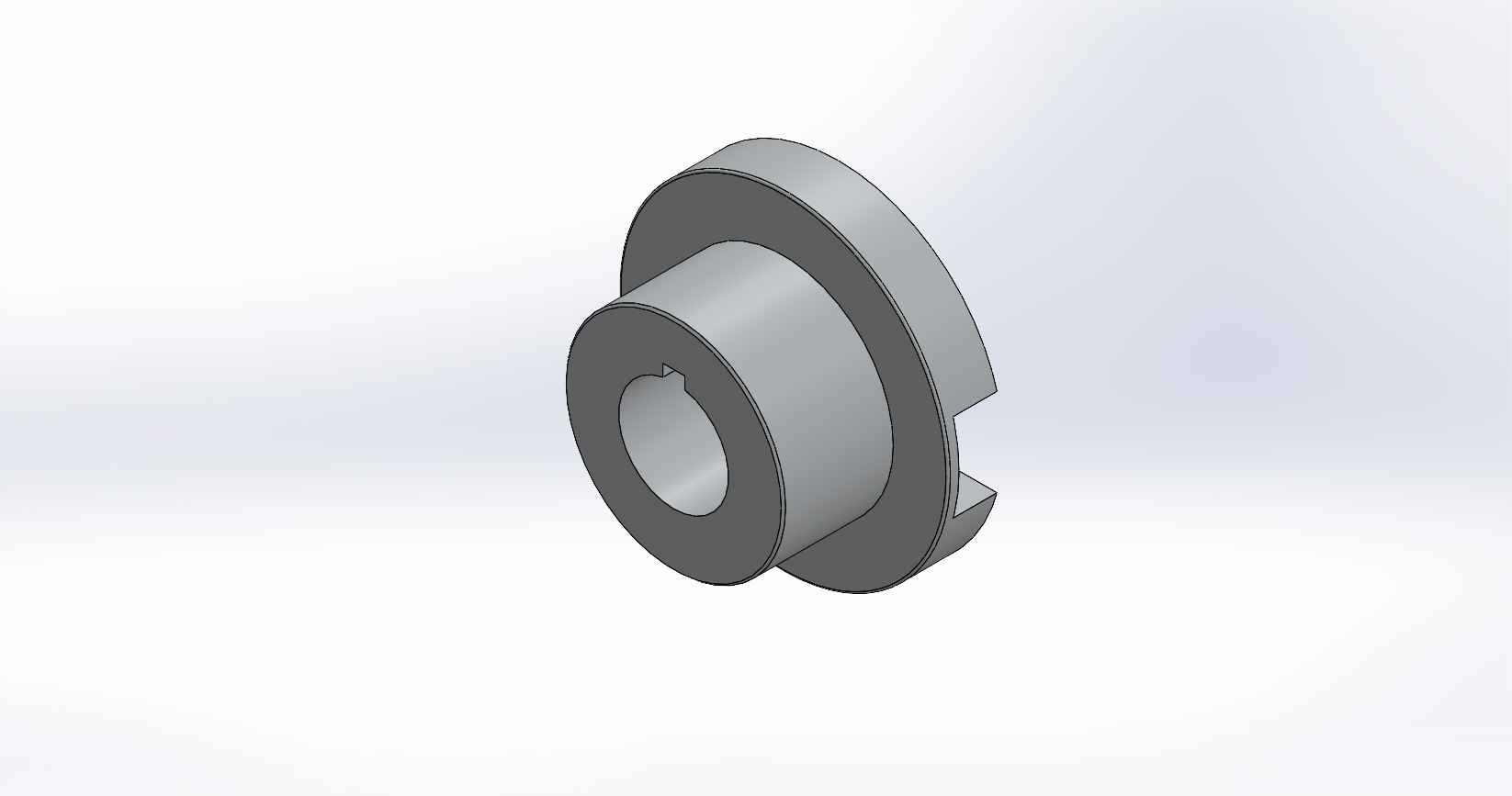

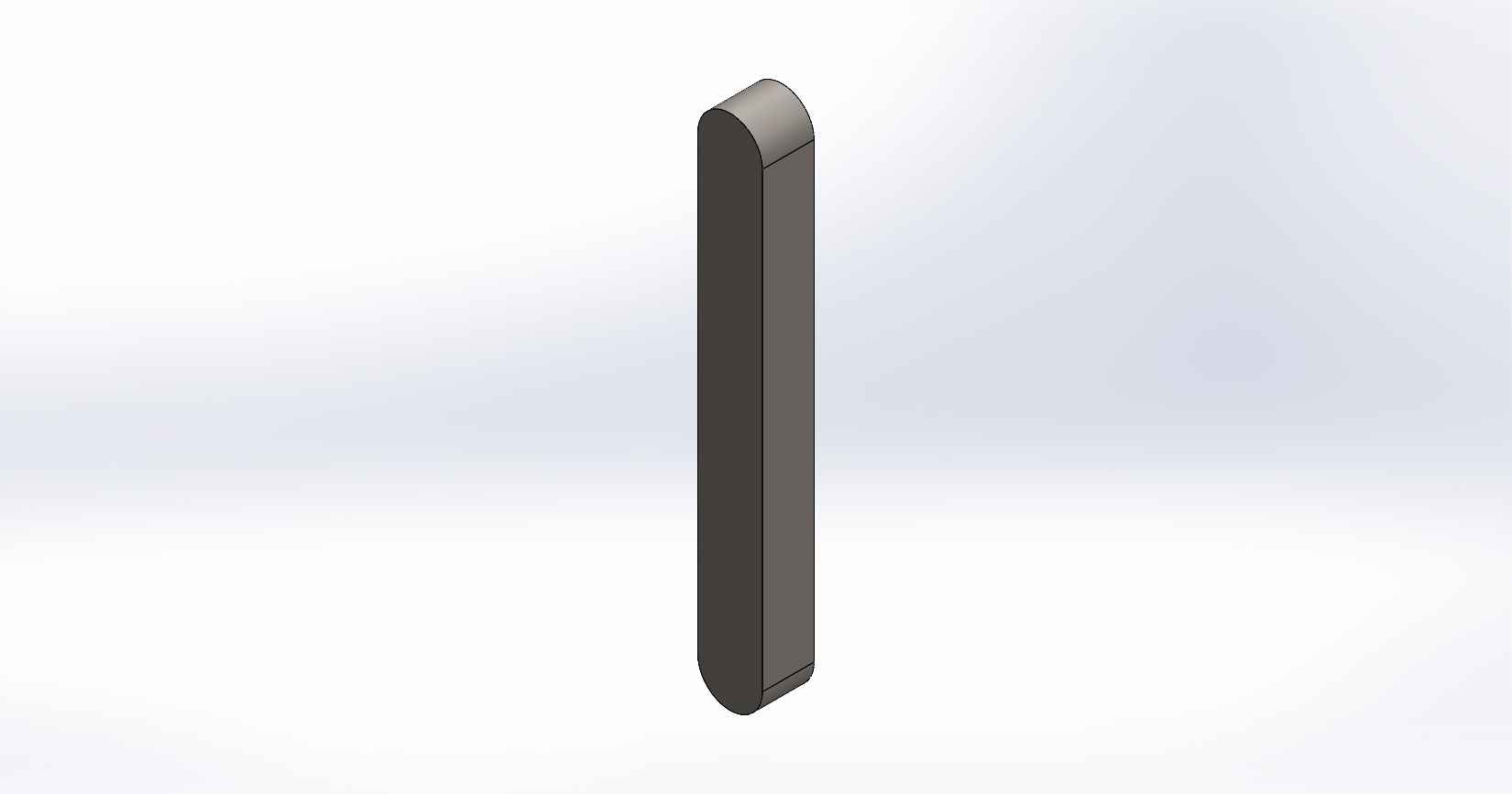

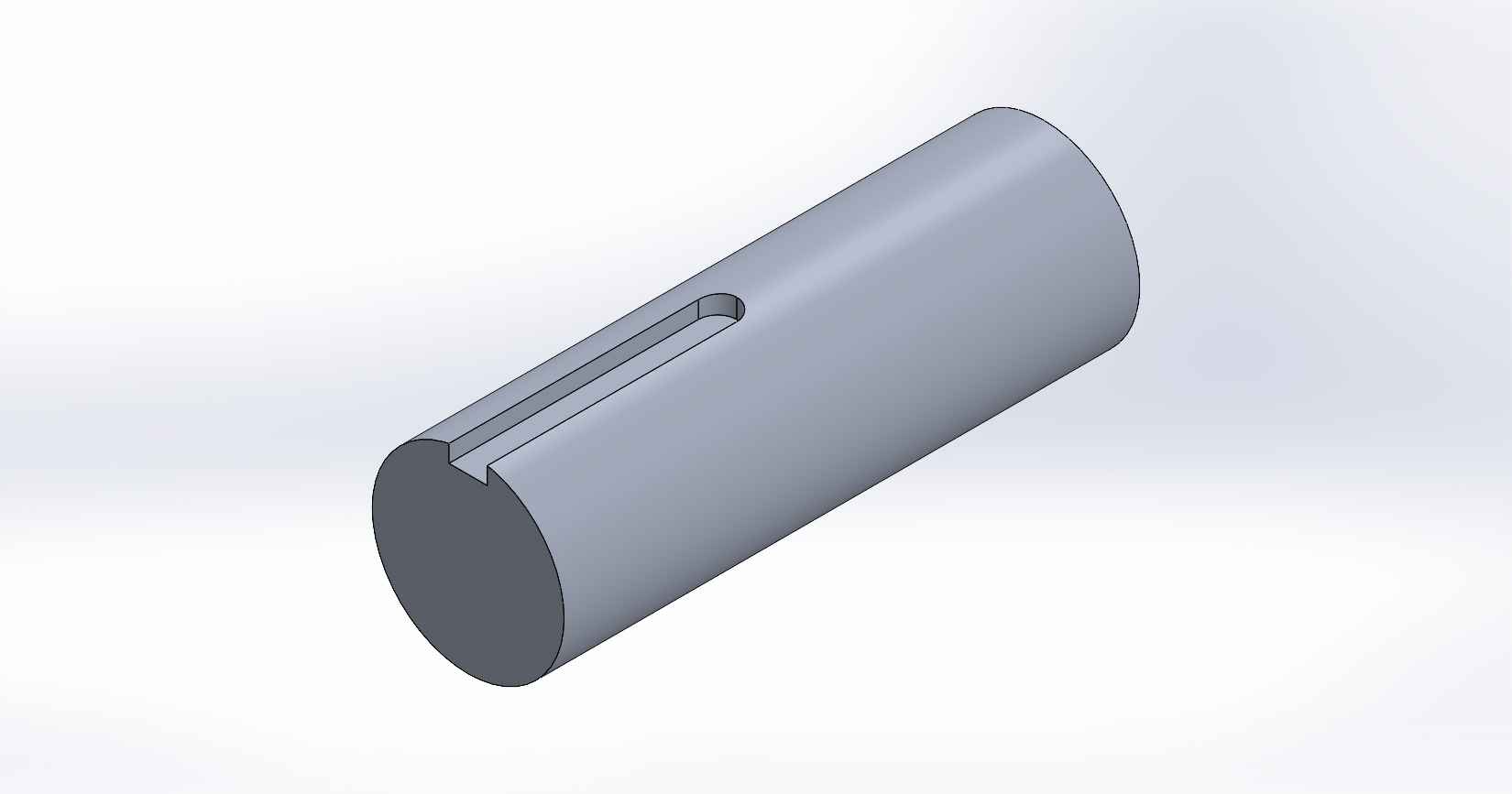

The Oldham coupling assembly in SolidWorks consists of several parts: a disc, two flanges, two shafts, and a key. Each component plays a crucial role in the functionality of the coupling. Disc: The disc is a flat circular component that acts as the central element of the Oldham coupling. It is designed to transmit torque between the two shafts while accommodating slight misalignment. The disc has a smaller diameter compared to the flanges and features keyways or slots on its surface. Flanges: The flanges are hub-like components with cylindrical shapes and larger diameters. They serve as the connection points between the disc and the shafts. Each flange has a central bore that matches the diameter of the respective shaft, allowing for a snug fit and secure attachment. Shafts: The shafts are cylindrical rod-like components that connect to the flanges. They transmit torque from an external source through the Oldham coupling assembly. Each shaft is inserted into the central bore of the corresponding flange and secured, typically using a key. Key: The key is a small rectangular component that fits into the keyways or slots on the disc and shafts. It ensures a positive connection between the disc and the shafts, preventing any relative rotation between them during torque transmission. When assembled, the Oldham coupling allows for slight misalignment between the shafts, thanks to the keyways on the disc. This flexibility helps to minimize stresses and vibrations caused by misalignment, ensuring smoother torque transmission. By creating the individual parts (Disc, Flanges, Shafts, and Key) and assembling them in SolidWorks, the Oldham coupling can be effectively represented and utilized in various mechanical designs. The assembly can be further modified, analyzed, or integrated into larger assemblies to meet specific engineering requirements.

Software

Categories

Keywords

OLDHAM COUPLING

Comments

Statistics

| 98 | views | |

| 0 | likes | |

| 0 | comments | |

| 2 | downloads |